How Digital Supply Chains Enhance Transparency and Trust to Protect Your Brand

How do we ensure that every thread, every fabric, and every product not only claim to be sustainable but truly embody responsible sourcing and environmental care?

Supply chains are facing new challenges as compliance regulations are continuing to evolve. Our recent webinar covered a few of the recent changes, highlighting both the difficulties involved with adapting and the potential for positive change. Adapting to these changes and using tools like Texbase can help simplify compliance and improve finished product data management. This article breaks down our most recent webinar and outlines critical compliance topics including Extended Producer Responsibility (EPR), the implications of PFAS regulations, and the evolving requirements of the CPSC's e-filing system.

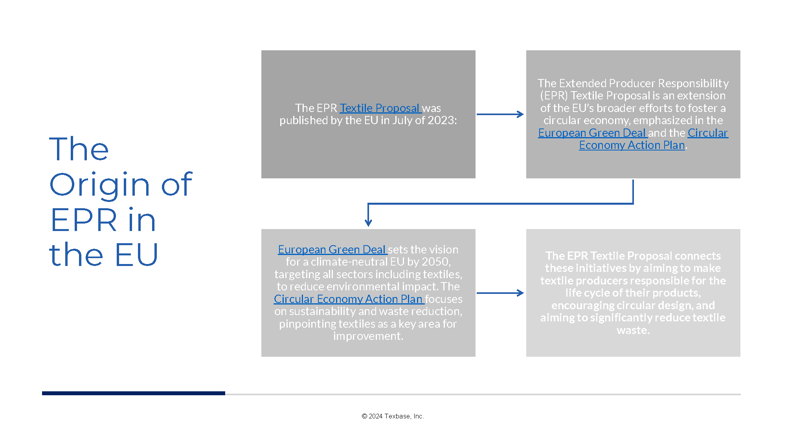

Extended Producer Responsibility originated in Europe with the European Green Deal that set the vision for a climate-neutral EU by 2050. EPR is designed to make producers accountable for the entire lifecycle of their products. This includes the adoption of circular economy principles which aim to minimize waste and promote recycling. In practice, this means that companies are required to enhance transparency and improve the environmental footprint of their products from creation to disposal.

Download the webinar slides and watch the full recording here.

With the tightening of regulations around Per- and Polyfluoroalkyl Substances (PFAS), companies are urged to reassess their use of these chemicals, known for their persistence in the environment and potential health risks.

Legislation in states like California is setting stringent limits on PFAS concentrations in consumer products, pushing companies to explore safer alternatives and adopt comprehensive management strategies. These changes underscore the importance of robust chemical management systems that ensure compliance and protect consumer safety. For a more detailed overview of the pending legislation, watch the full presentation here.

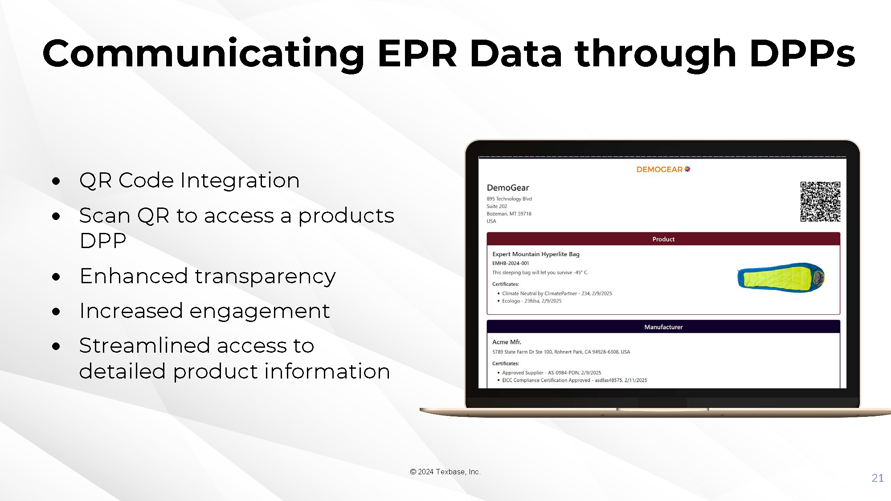

The integration of Digital Product Passports (DPP) is set to transform product lifecycle management by enhancing data transparency. DPP enable detailed tracking of a product's material contents and environmental impact, facilitating better recycling and reuse.

France's recent initiative requires companies to disclose extensive product information, influencing broader adoption across industries. To read about France's disclosure law, watch the full presentation here.

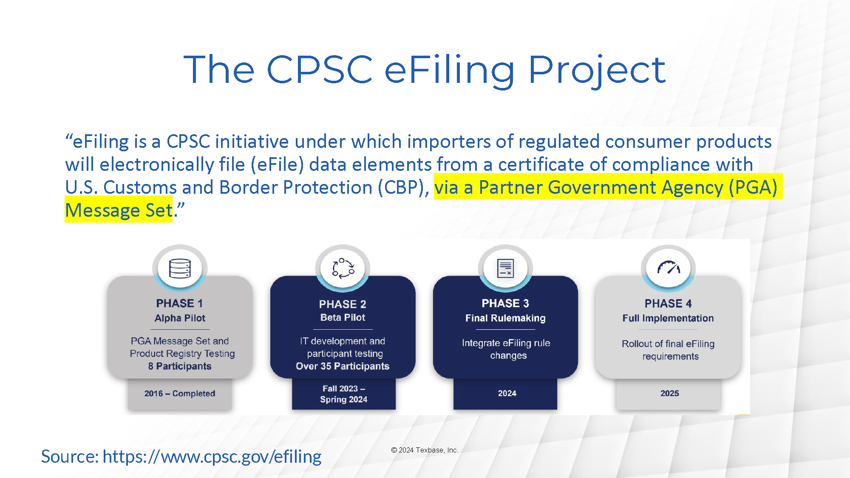

Adapting to digital transformations, the Consumer Product Safety Commission (CPSC) is implementing an eFiling system to streamline the submission of compliance documents. This move towards electronic data management requires companies to be proactive in maintaining up-to-date certificates of compliance, ensuring that all products meet the required safety standards before they reach the market.

Thank you to everyone who joined the live webinar. Please see below for answers to some of the questions we received during the live session. Our aim is to guide you toward the appropriate resources so that you can find the answers you need.

* Please note, while we strive to provide accurate and useful information, please consult qualified legal experts to ensure that the actions you take are tailored to your specific legal and regulatory requirements.

Topic: PFAS

Under California AB 1817, products that count as "severe wet conditions" include outdoor apparel that is used for "extreme and extended use" in outdoor sports. These products are meant to provide protection against extended exposure to extreme rain conditions or extended immersion in water or wet conditions.

Examples of products explicitly mentioned include outerwear for offshore fishing, offshore sailing, whitewater kayaking, and mountaineering.

It would therefore be prudent to evaluate products against the criteria mentioned in AB 1817 and seek further guidance from legal counsel to determine if specific ski or snowboard outerwear qualifies under the "severe wet conditions" exemption.

Source: https://leginfo.legislature.ca.gov/faces/billTextClient.xhtml?bill_id=202120220AB1817

A: As far as we can discern, the compliance certificate for California AB 1817, regarding textile articles and the prohibition of perfluoroalkyl and polyfluoroalkyl substances (PFAS), must contain the following information:

A: On Jan. 9, 2024, OEKO-TEX® implemented a new 100 mg/kg limit on total fluorine for all textile and leather product classes, effective Jan. 1 for Standard 100, Eco Passport, Leather Standard, and Organic Cotton certifications. This change is intended to enable "all OEKO-TEX® certifications to remain compliant with the U.S. regulations on PFAS."

Source: https://www.oeko-tex.com/en/news/press-releases/oeko-tex-new-regulations-2024-press-release

A: Detection limits for PFAS (perfluoroalkyl and polyfluoroalkyl substances) in textiles vary based on the testing methods and specific PFAS compounds targeted. California's AB 1817 sets clear thresholds for PFAS content in textile products: starting January 1, 2025, the limit is 100 ppm, which tightens to 50 ppm by January 1, 2027. Testing protocols must therefore be capable of accurately measuring PFAS concentrations to comply with these limits.

For detailed guidance on the recommended testing approaches for PFAS in textiles, the AFIRM Group provides a comprehensive document. It outlines methodologies and considerations for phasing out PFAS in compliance with regulations like AB 1817. You can access this resource here, which is instrumental for manufacturers and testing laboratories in adhering to these legislative requirements.

Source: https://afirm-group.com/wp-content/uploads/2023/09/AFIRM_Phaseout_PFAS_2023_0831.pdf

How do we ensure that every thread, every fabric, and every product not only claim to be sustainable but truly embody responsible sourcing and environmental care?

In the textile industry, the importance of performance in sustainable materials cannot be overstated.

Data Is Now Paramount and Digital Supply Chains Are Critical. It used to be that cost was the greatest factor in sourcing and selling products. No more. Now it’s all about the data.